Industrial Projects

Probabilistic optimization of PSC girder bridges

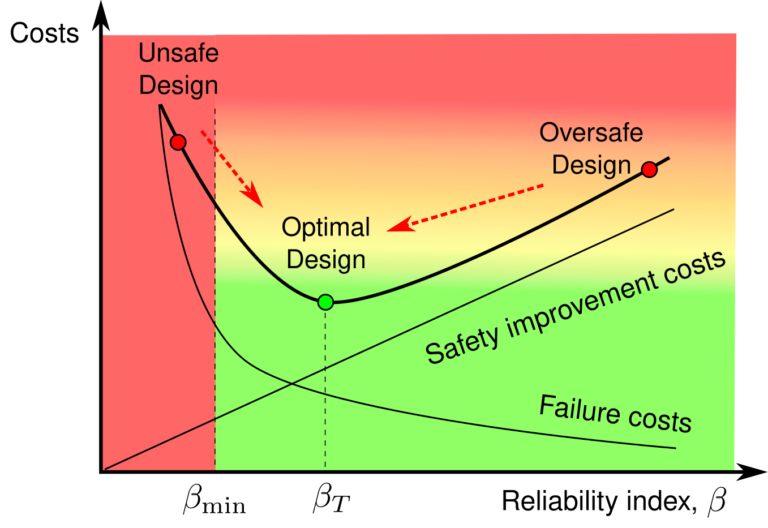

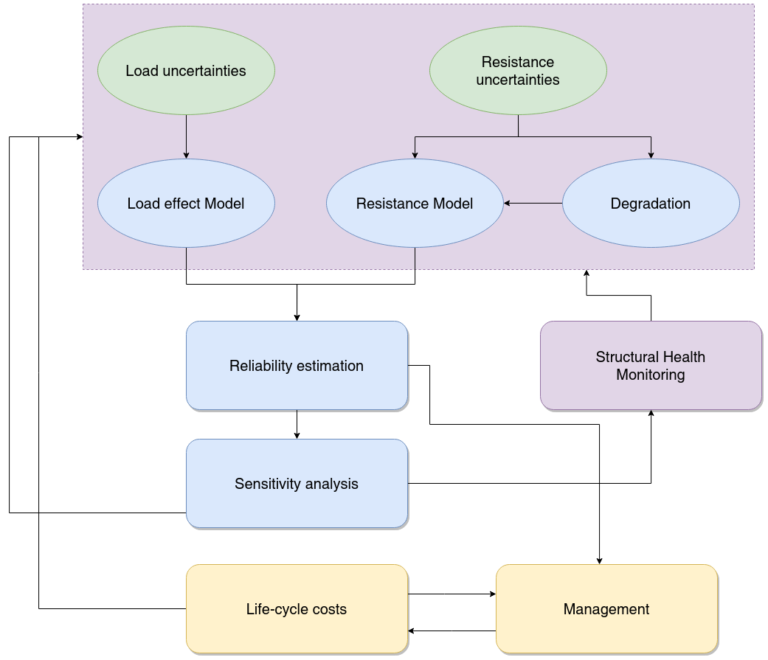

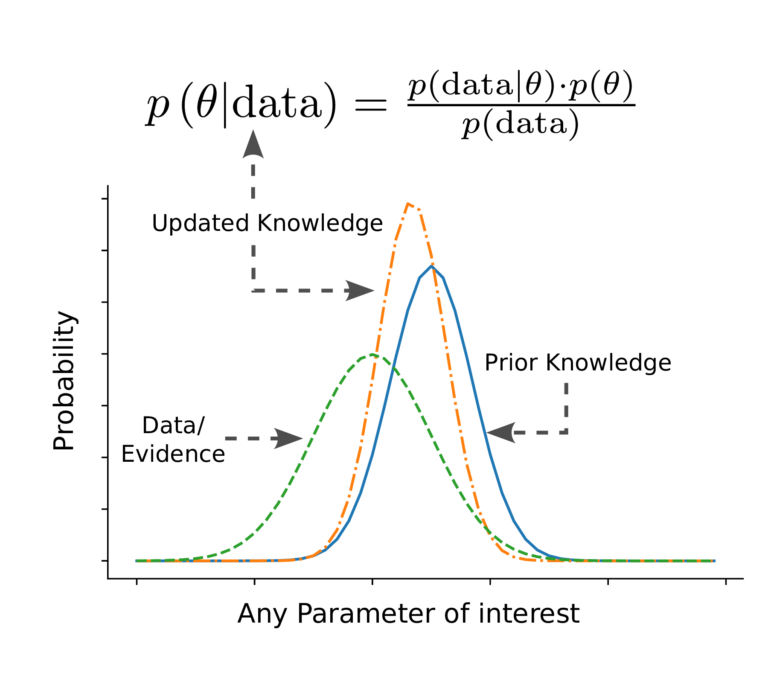

In this project, I developed data science solutions for a major transport client to help them optimize their rail bridge assets. I played a lead role in developing these data-science solutions, handling clients, managing the instrumentation of assets for performance analytics, and writing technical reports. I was also responsible for instrumenting data acquisition systems on transport assets and providing the clients with asset health monitoring data analytics. I developed programmed probabilistic data science solutions for predicting the performance of their assets using reliability forecasting principles. I co-developed new statistical approaches for designing bridge assets and implemented them in a Python FOSS PySTRA. I utilized Bayesian statistics and extreme value theory to forecast rare events in asset performance. I also implemented OCR solutions in Python to extract material strength data provided by the Clients in the form of images. I developed Causal inference models to predict the material strength and hierarchical Bayesian models for predicting performance sensor measurements. Consequently, I optimised their assets by 20%, leading to a significant reduction in capital employed, material utilized, and carbon emissions.

Structural reliability assessment of corroding steel truss bridge

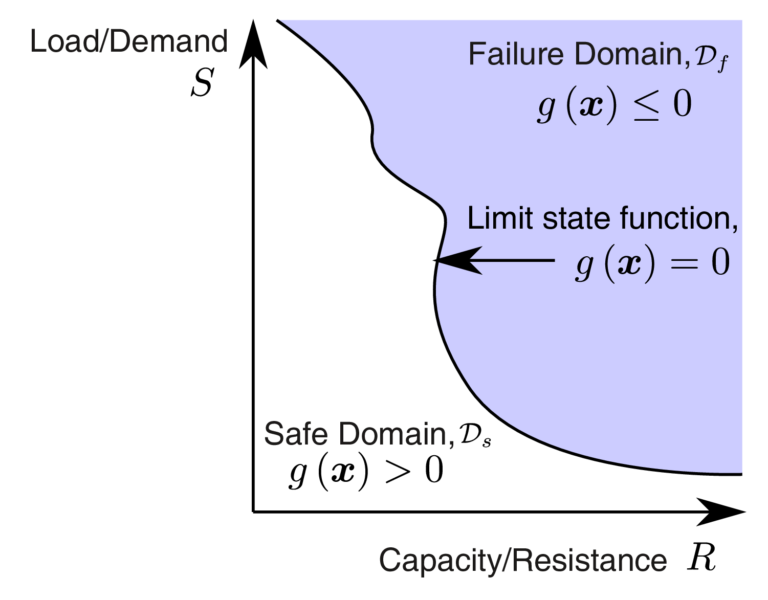

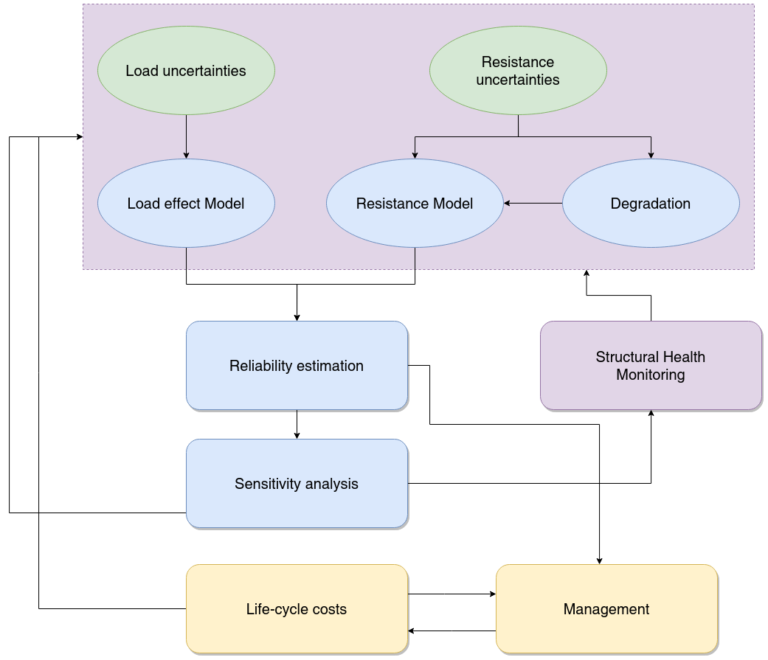

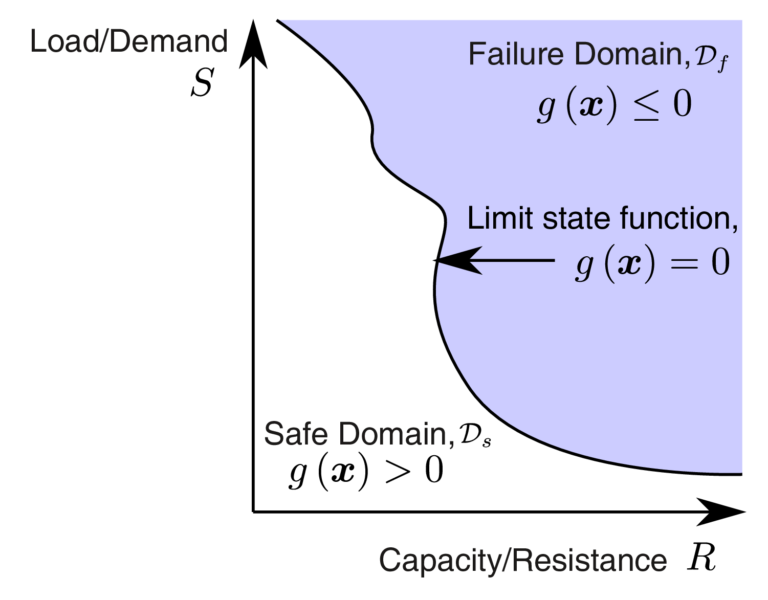

In this project, I developed a probabilistic performance prediction model for a corroding three-span steel truss bridge in Queensland, Australia using physics-informed data-science techniques. Facing challenges due to corrosion, I refined the performance assessment model for critical girder and bracing members to prolong the bridge’s service life while minimizing costly repairs. Developing a scalable framework, I

addressed various probabilistic modeling challenges, including load uncertainties and resistance factors. Leveraging Python, I conducted extensive finite element analyses using libraries like sectionproperties and Pystra. I employed Bayesian statistics and conducted over 6000 reliability analyses, utilizing algorithms like First Order and Second Order Reliability Methods, and Monte Carlo simulation. Additionally, I co-developed a novel mathematical formula for tailored load combination factors, resulting in 300% more efficient designs. This initiative helped the client save $60 million in maintenance costs. Further, I developed a risk rating factor as a maintenance aid and actively engaged in client meetings, presentations, and co-authoring technical reports.

- A Generalized Framework for Reliability Assessment of Bridges using Adjusted Partial Safety and Combination Factors

- A value of information framework for quantifying the value of reliability assessment for a steel railway truss bridge

- Reliability assessment of steel truss railway bridges at ultimate limit state under combined loads